Chapter1: What is a lowbed trailer?

1.1: How long is a lowbed trailer?

1.2: How wide is a semi low bed trailer?

1.3: Lowbed trailer dimensions

1.4: Lowbed semi trailer loading capacity

1.5: How much does a low bed truck trailer weight?

Chapter 2: Common structure and transportation of low bed trailer

2.1 The first structure of the low bed trailer

2.2 The second structure of lowbed trailer

2.3 Loading method of lowbed trailer

Chapter 3: Factors to Consider When Purchasing a Low Bed Trailer

3.1 Working platform of lowbed trailer

3.2 Low bed trailer ramp

3.3 Lowbed trailer suspension

Chapter 4: Low bed truck trailer load capacity

4.1 What factors will affect the load capacity of the lowbed trailer ?

4.2 What is the tons of the lowbed trailer ?

4.3 What is the height of the bearing surface of hydraulic low bed trailer ?

Chapter 5: Lowbed Trailer load test and marine transportation

5.1 Loading test of lowbed trailer

5.2 Low bed semi trailer marine transportation

Chapter 6: Applications of lowbed trailer

Chapter 7: How does a low bed trailer work ?

Chapter 8: How to choose a suitable lowbed trailer (excavator trailer) ?

Chapter 9: What are the factors affecting the passability of lowbed trailers ?

Chapter 10: Why TITAN lowbed trailer price more expensive?

Chapter 11: Advantage of TITAN low bed truck

Chapter 12: Package and delivery of low bed truck for sale

Chapter 13: Difference types of lowbed trailer

Chapter 14: What is the main advantage of a low bed trailer over a flat bed?

Chapter 15: Different type ramps of lowbed trailer

Chapter 16: Components of the lowbed trailer

Chapter 17: What is the cost of low bed trailer?

Chapter 18: What is the difference between lowboy and lowbed?

3 axle Low bed trailer for sale

100t lowbed trailer for sale

4 line 8 axle 150 ton lowbed trailer

Spot discount, welcome to contact us

Lowbed Trailer are usually used to transport a variety of machinery and equipment, heavy equipment, highway construction equipment, large tank body, power station equipment, and various excavators, and are used to transport heavy vehicles (such as tractors, coaches, Subway truck head, etc.), rail vehicles, mining machinery, forestry machinery, construction machinery (such as excavators, bulldozers, loaders, pavers, cranes, etc.) and other heavy-duty cargo.

The lower the platform height of the lowbed trailers, the better the stability and safety. Our lowbed trailer has a large carrying capacity when transporting extra high and medium cargo. TITAN lowbed trailer height from ground is usually 1300mm. If you have special needs, TITAN can also customize it for you.

Lowbed trailers are constructed with a strong and durable frame to handle the weight and stress of heavy loads. They often have multiple axles, which help to distribute the weight evenly and provide stability during transport. Some lowbed trailers are equipped with hydraulic systems that enable them to lower the rear end further, making it easier to load and unload heavy equipment.

Overall, lowbed truck trailer play a crucial role in facilitating the transportation of heavy and oversized cargo, ensuring that it can be moved securely and efficiently to its destination.

What is the purpose of a low bed truck?

1. Heavy Equipment Transport: Low bed trucks are commonly used to transport heavy machinery and equipment, such as excavators, bulldozers, cranes, and industrial machinery. Their low deck height and sturdy construction enable them to handle the weight and dimensions of these large and heavy loads.

2. Oversized Cargo Transport: Low bed trucks are ideal for hauling oversized cargo that cannot be easily accommodated by regular trucks or trailers. This can include items like prefabricated structures, oversized tanks, wind turbine components, or construction materials with non-standard sizes.

3. Construction Industry: Low bed truck play a crucial role in the construction industry by transporting construction machinery and equipment to and from job sites. They are essential for moving heavy construction equipment between locations, ensuring that projects can proceed smoothly and efficiently.

4. Safe and Stable Transport: The design of low bed truck, with their strong frames, multiple axles, and specialized suspension systems, ensures safe and stable transportation of heavy loads. This minimizes the risk of accidents, damage to the cargo, and maintains road safety.

1.1: How long is a lowbed trailer?

The 2 axle low bed trailer length: 11500mm

The 3 axle low bed trailer for sale length: 13000mm

The 4 axle lowbed truck trailer length: 15800mm

1.2: How wide is a semi low bed trailer?

Most popular semi low bed trailer width: 3000m. Can be customized if you have special needs.

1.3: Lowbed trailer dimensions

2 axle low bed trailer price dimensions: 11500*2500*2900mm

3 axle low bed semi trailer dimensions: 13000*3000*3400mm

4 axle lowbed trailer for sale dimensions: 15800*3000*3400mm

1.4: Lowbed semi trailer loading capacity

2 axle lowbed trailer capacity: 30-40 ton

3 axle low bed truck trailer capacity: 50-80 ton

4 axle lowbed trailer loading capacity: 90-120 ton

1.5: How much does a low bed truck trailer weight?

2 axle lowbed for sale: 9-11 ton

Tri axle lowbed trailer for sale: 10-12 ton

4 axle low bed truck trailer: 11-13 ton

There are many structures and styles of lowbed trailer. Below we introduce the two most common styles.

Low bed trailer usually use a high-low frame, that is, the front section of the frame is a gooseneck (the traction pin at the front section of the gooseneck is connected to the traction saddle on the tractor, and the back end of the gooseneck is connected to the low bed semi trailer frame).The middle part is the cargo platform (the lowest part of the frame).

This structure can transport a variety of heavy equipment, can also transport other general cargo, can also transport 40-foot containers, 20-foot containers. The export volume of machine carriers of this structural style to Africa is the largest. Low bed trailer carrier for sale NZ India price.

Another structure commonly used in low bed truck trailer: a concave beam frame. The front section of the frame is gooseneck (the traction pin at the front section of the gooseneck is connected to the traction saddle on the tractor, and the back end of the gooseneck is connected to the low bed truck trailer frame), the semi low bed truck trailer middle section is the cargo platform (the lowest part of the frame), and the rear end is Wheel frame (including wheels).

When loading mechanical equipment on a lowbed trailer, it is usually loaded from the rear of the lowbed trailers, that is, by moving the mechanical equipment from the rear wheel frame or removing the wheels, and then fixing the mechanical equipment to the low bed loader.

heavy duty low bed semi trailers dimensions drawing

Spot discount, welcome to contact us

The low bed truck can also carry a wide range of goods, which is suitable for the transportation of various steels such as a variety of mechanical equipment, large objects, highway construction equipment, power station equipment and machinery.

What is the difference between detachable low bed and semi low bed trailer? he major difference in lowboy trailer is that the gooseneck can be removed. When using a low bed trailer, the heavy cargo is loaded from the rear part. However, the cargo is loaded from the front part when using a rgn lowboy trailer.

The lowbed trailer main cargo platform is low, which ensures the stability of transportation and is suitable for carrying various types of engineering machinery, large equipment and steel.

Heavy duty lowbed trailer Frame; Lightweight low loader Frame

Different frame styles determine its carrying capacity.

There are three styles of low loader trailer ramps, the most common is spring ladders. There are also ordinary hydraulic ramps and folding hydraulic ladders.

There are three styles of lowbed trailer suspension. The most common are leaf spring suspension, airbag suspension, and axis suspension.

low bed trailer for sale vs flatbed trailer

There are many tonnages for low bed trailer for sale, Our most common tonnages are 15 tons, 30 tons, 40 tons, 60 tons, 80 tons, 100 tons, 120 tons, 150 tons, 200 tons. We can provide customized services according to the actual situation of transportation.

The load capacity of the lowbed trailer truck is mainly achieved by the frame, that is, the most important factor affecting the lowbed trailer load capacity is the frame. The stronger the frame, the better the carrying capacity.

Low loader trailer for sale Tires have different models and designs, so tires also have a great impact on the load.

Axles, the more axles, the greater the load. Common models of axles are 13 tons, 14 tons, 16 tons and 20 tons.

Other: the thickness of suspension, the thickness of leaf spring, etc.

There are many tonnages of drop heavy haul trailer we can provide, such as 15 tons, 30 tons, 40 tons, 60 tons, 80 tons, 100 tons, 120 tons, 150 tons, 200 tons. Customized production according to the actual situation of transportation.

Many customers choose conventional models under 100t lowbed for sale.

The most common hydraulic lowbed trailer height is 125cm. The low plate height purchased by African customers is 90cm, 100cm, 125cm, 130cm, and the minimum height can be 65cm. Double drop deck trailer with beavertail for sale craigslist dimensions.

4.4 What determines the load capacity of a lowbed trailer?

The load capacity of a lowbed trailer is determined by several factors:

1. Trailer Design: The structural design, including the materials used and the overall engineering of the trailer, plays a crucial role in its load capacity. Lowbed trailers often have a reinforced structure to handle heavy loads.

2. Axle Configuration: The number and configuration of axles significantly affect load capacity. More axles allow for a lower weight distribution, increasing the maximum load a lowbed trailer can safely carry. Common configurations include 3, 4, or more axles.

3. Weight Ratings: Each lowbed trailer will have specific weight ratings, including Gross Vehicle Weight Rating (GVWR) and Payload Capacity. The GVWR indicates the maximum weight the lowbed trailer can carry, including its own weight.

4. Length and Width: The lowbed trailer's dimensions can affect its capacity. Longer trailers can often accommodate larger loads, but they must also comply with road regulations regarding size limits.

5. Suspension System: The type of suspension system used influences load capacity and stability. Air ride suspension, for example, can provide better weight distribution and handling for heavy loads.

6. Tire Ratings: The tires on the lowbed trailer must be rated for the expected load. Higher-rated tires can support heavier weights without risk of blowouts or failure.

7. Regulatory Compliance: Load capacity can also be influenced by relevant regulations, which may impose restrictions based on road conditions and safety standards.

By considering these factors, the total load capacity of a lowbed trailer can be accurately assessed to ensure safe and efficient transport of heavy equipment or materials!

Spot discount, welcome to contact us

75 ton lowbed trailer for sale package and shipping

All heavy haul trailer is tested for carrying capacity after production is finished.

In order to prevent the lowbed trailer paint from being corroded by seawater, we spray a layer of wax on the surface of the Lowbed Trailer before shipping and then cover it with a waterproof rain cloth.

3 axle 40ft lowbed trailer dimensions for sale craigslist truck paper auction

5.3 Delivery of lowbed trailer for sale

Before delivery, all TITAN low bed trailers need to undergo a load-carrying capacity test to ensure that there are no problems with our lowbed truck trailers when they leave the factory.

Although there are many modes of delivery, there are only two most commonly used modes for low bed trailer, by container and ro-ro ship.

1. By container:

After technological improvements to lowbed trailer for sale, TITAN has formulated a container transportation plan for low bed trailer. We can load a low bed trailer into a container by removing the gooseneck, frame, etc.

When a low bed trailer is transported inside a shipping container, it benefits from an added layer of protection. The container shields the trailer from external elements such as weather conditions, road debris, and potential damages during transit. It also provides security against theft or unauthorized access.

A lowbed trailer loaded in a container can seamlessly transition from one mode of transport to another, such as road, rail, or sea. This streamlined process reduces handling and minimizes the risk of damage or delays during transfer.

2. By ro-ro ship:

If you choose to transport by ro-ro ship, we will spray a thick layer of wax on the low bed trailer, and then wrap the body with tarpaulin. This is also to reduce the low bed trailer from being corroded by seawater during transportation.

Ro-ro ships offer efficient transportation for low bed trailers. These ships can accommodate a large number of vehicles, allowing for the transport of multiple trailers at once. This maximizes the cargo-carrying capacity, improving efficiency and potentially reducing shipping costs per unit.

Ro-ro shipping offers flexibility in terms of the type and size of lowbed trailers that can be transported. Whether it's a standard lowbed trailer or an oversized one, ro-ro ships can accommodate a wide range of vehicle dimensions and configurations. It provides accessibility to different markets and destinations.

Low bed trailers can transport heavy cargo in different industries. Here are the most common uses of heavy-duty trailers.

Heavy vehicles: Vehicle manufacturers use low bed trailers to transport heavy vehicles from one showroom to another. The transporters are used to move the vehicles from the port to showrooms and sometimes to clients.

Construction: semi low bed trailers are used in the construction industry as well. Heavy duty vehicles are commonly used in the construction of roads and bridges.

Some construction equipment and blocks cannot be transported with normal semi-trailers. Low bed trailers are used to transport concrete blocks to the construction sites.

Mining machinery: Mining requires heavy machinery for drilling and transporting materials including crude oil and minerals. The machinery is assembled offsite and then transported to the mining sites using low bed trailers.

The semi low bed trailer is preferred because of the structure of mining machinery. Mining equipment is perhaps the heaviest cargo that machinery manufacturers transport on the road.

Windmill components: The components of windmills are usually assembled in a factory and then transported to their sites. Similar to other heavy cargo, the components are wide and heavy.

The components cannot fit on a closed trailer because of their design and structure. Lowboy trailers are an efficient way of transport these components to their site.

3 axle low bed truck feedback

3 axle low bed truck feedback

1. Low bed trailer have flatbed, concave beam and tire exposed structures, and the longitudinal beams are straight or gooseneck. The frame is stepped, and the cross section of the longitudinal beam is I-shaped, which has the characteristics of high rigidity and high strength.

2. The main plane of the frame and cargo platform is low, which ensures the stability of transportation, and is suitable for carrying all kinds of construction machinery, large equipment and steel.

3. It adopts three-axis balanced, two-axis balanced or rigid suspension, with mass balance blocks installed between the front and rear leaf springs, which can change the deflection of the front and rear leaf springs by the same amount and balance the forces on the front and rear axles;

4. The low bed trailers series products are suitable for a variety of mechanical equipment, large objects, road construction equipment, large tanks, power station equipment and machinery. They are widely used, efficient and fast. The whole heavy load trailer adopts advanced computer-aided design software, which is optimized for flexible and diverse design. The load-bearing surface of the frame is designed according to user requirements to meet the transportation of various special goods.

5. Trailers are divided into semi-trailers and full-trailers. The semi-trailer axle is placed behind the center of gravity of the vehicle (when the vehicle is evenly loaded) and is equipped with a coupling device that can transmit horizontal or vertical force to the tractor. The front part of the carriage rests on the pallet of the tractor. low loader trailers are generally under 13 meters. The load of the trailer is fully borne by itself, and it is connected with the locomotive only by hooks. The locomotive only provides power to help the lowbed full trailer overcome the frictional resistance of the road. It can stand upright on its own tires. Generally around 6.5 meters.

lowbed trailer ready for painting

Spot discount, welcome to contact us

The ordinary low bed trailers, RGN trailers, and low loaders have their advantages and disadvantages. We can provide you with a suitable heavy duty lowbed trailers according to your needs.

Cargo dimension: It is important to consider the dimensions of your cargo when choosing a trailer model. Different axle configurations carry different cargo equipment. For your trailer to be more efficient, the weight should be evenly supported and distributed over the trailer.

If the height of your cargo is too high, choose a low loader, an RGN trailer, or a folding gooseneck trailers. The models allow you to lower the rear part and reduce the total height of the cargo.

Therefore, you should know how your cargo equipment will be loaded on your trailer and then choose the design that matches it.

Price: The prices of low bed trailers vary with their load capacities and performance.

If you are looking for a trailer to transport heavy cargo at the least cost possible, the ordinary low bed trailers are your best choice.

Cargo weight: The right model will depend on the maximum weight of your cargo. If you intend to transport more than 70 tons, consider buying low loaders, RGN trailers. Lowering the center of a heavy load increases its stability.

Maintenance costs: The buying price is not the only cost you will incur on your heavy load trailer. You have to service the trailer regularly to maintain its optimal performance.

Manufacture Quality: Check on the quality of welding done on the trailer. Good quality welding can guarantee strength to your low bed trailer structure. The welding joints contribute a lot to the fatigue resistance of your low bed trailer.

The sharp geometry created by welding joints largely reduces the fatigue resistance of that section when compared to the base material.

There are residual stresses that get introduced during welding as a result of the heat used during the process. However, there is a way that these stresses can be minimized. You can tell by observing the quality of weld on the trailer framework.

Your focus on fatigue resistance should not only be based on the micro-structures of the base material, its hardness and the heat affected zones.

100t lowbed for sale in factory

Semi trailer theory research shows that the passability of a low bed truck refers to the ability of a car to pass through various road conditions at a sufficiently high average speed under a certain load.

There are many influencing factors for vehicle passability. From the perspective of giving full play to the power of the drop deck trailer, driving speed, car wheels, differentials, driving methods, etc. have an impact on passability; from the perspective of the vehicle technical structure, the minimum ground clearance of the step deck trailer, Longitudinal passing radius, lateral passing radius, minimum turning diameter, etc., reflect the passing capacity of the vehicle; from the perspective of highway technical indicators, the carrying capacity, slope, bend radius and clearance of the highway limit the passing of the vehicle.

Heavy-duty low loader trailer transportation due to their ultra-long, ultra-wide, and ultra-high characteristics, determine that they are different from ordinary vehicles during transportation, especially in terms of passability, the strength, clearance, and technology of roads, bridges, and tunnels along the way. The conditions have special requirements.

Engineering practice shows that during heavy transportation, air obstacles, road or bridge cargo restrictions, obstructions on roads and facilities above, etc. often impede the passage of transportation. According to the characteristics of heavy transportation work and transportation requirements, it can be summed up. The passability of the vehicle includes the following aspects.

Drawing of TITAN 4 axle 100t lowbed semi trailer for sale

Road load capacity

The load tonnage of large parts transportation is generally large, and the roads and bridges that need to pass through the ground and have large loads should have a large area with sufficient load capacity. Therefore, the roads and bridges need to be analyzed and checked. If it does not meet the strength requirements, it will inevitably cause the vehicle-cargo system to be unstable and cause a safety accident.

Horizontal and longitudinal capacity

The cross slope and longitudinal slope of the highway have a great influence on the stress system of transportation vehicles and cargoes. From the previous vehicle stability analysis, it can be seen that if the cargo has a certain strapping method, if its maximum lateral and longitudinal tilt angle exceeds the allowable The angle will destroy the stability of the transportation vehicle, which means that the transportation vehicle cannot pass through such a steep road.

shipment of low bed trailer

Curve passing ability

Usually highways are designed according to highway technical standards, but because the large-sized transportation lowbed trailer for sale is different from the ordinary design vehicles based on highways in terms of both the shape of the equipment trailer and its turning ability, it is necessary to check the curve data of the highway along the way to Determine whether the vehicle can pass safely.

Overall capacity

Due to the ultra-high and ultra-wide width of large objects, the clearance size of roads, bridges, tunnels and buildings on the road must be passed to ensure the safe passage of transportation vehicles.

Spot discount, welcome to contact us

1. Weight of lowbed semi trailer

First of all, the different types of lowbed semi trailers of the same type have different dimensions, which will cause the effective volume of the trailer’s box and the weight of the body to be different. Because the main processing material of the trailer is steel, the price is determined by the weight of the steel.

2. Material used by semi trailer

Second, for trailers of the same type and weight, the price will vary greatly depending on the strength of the selected steel.

According to the current market price, high strength sheet material will be 150 US dollars a ton more expensive than ordinary steel. Taking a 13-meter fence semi trailer as an example, the weight of the upper body is about 3 tons. The materials used are different, and the cost of the vehicle will be about 500 US dollars. The price difference between stainless steel materials will be even greater.

Frame of Lowbed Semi Trailer in TITAN Factory

3. Lowbed trailer accessories

Third, accessories of different brand materials will directly lead to price differences. For example, the price of tires of different brands will be different, there will be differences between the air chambers of different materials, aluminum alloy and ordinary carbon steel. Among them, the price of axles of different brands is very large, and the difference between foreign brands and Chinese brands will be 1500 US dollars.

Besides, the rim will also cause a large price gap for lowbed trailers. The application of aluminum alloy rims has become more and more popular with customers. A record of over 12 pounds has confirmed that The steel ring is about 240 kilograms light, but the price gap will also be more than a thousand dollars.

Some customers said that looking at the trailer is similar, why is your price expensive? Today I will use TITAN tri axle low bed trailer to illustrate the reasons.

If you buy cheap but poor quality semi trailer, you will make up for it in the future. The truck head will cost tens of thousands to buy, so you better spend a few thousand dollars on a better quality semi trailer.

Drawing of 4 axle lowbed truck trailer

Drawing of 4 axle lowbed truck trailer

Spot discount, welcome to contact us

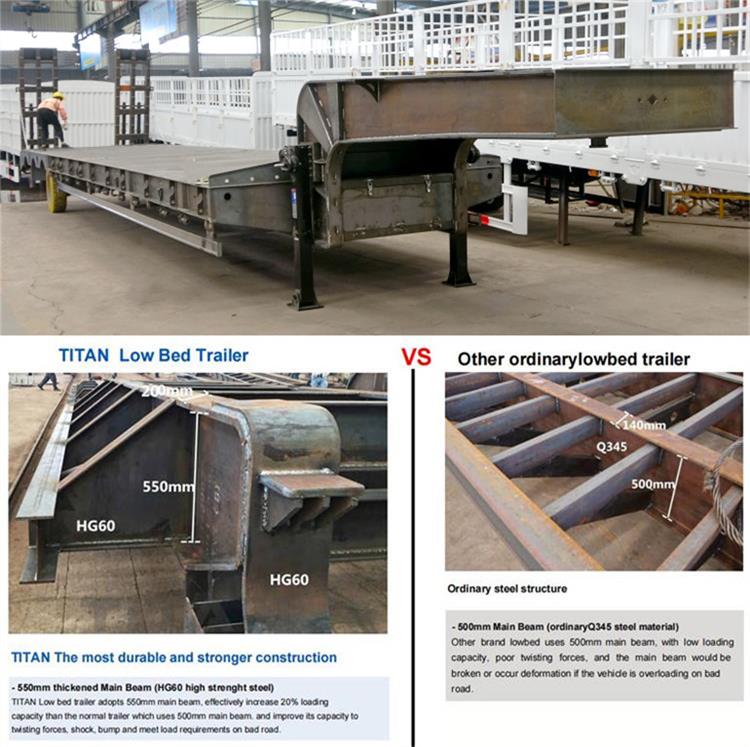

1. Frame of low bed truck

Main Beam: The main beam of TITAN low bed truck trailer is made of Q460C high strength structural steel. Q460C steel has a yield strength of ≥620Mpa, which is more durable and stronger than ordinary steel. Its bearing capacity is 5 times that of the trailer made of Q345 steel.

TITAN low bed trailer main baem adopts a height of 500mm and a thickness of 14mm. The thickness of upper plate is 22mm, the thickness of lower plate is 22mm and the width of upper and lower plate is 220mm.

Other factories use Q345 steel main beam for the low bed truck. The width of the upper and lower plates is 140mm. The load-bearing capacity of the frame is 27% lower than that of TITAN.

Side Beam: The side beam adopts "H" shape design and is welded with T700 high strength steel and it is designed H shape with a height of 300mm, width of 140mm and thickness of 8mm. Its bearing capacity is twice that of other steel, and it will not deform after ten years of use. Anti - turbulence ability increased about 3 times.

Side support: The beam design, our side support beam use Q460C high strength structural steel. The thickness is 6mm, and the inclined support is Q460C with a thickness of 6mm. Effectively connect the main beam and side beam together as a whole. Bearing capacity anti - turbulence capacity greatly increased, the service life more than 10 years.

All trapezoidal scales for the whole vehicle, G-type scales (higher strength than ordinary C-type scales) are used for the vehicle weighing less than 60 tons.

Frame of low bed truck trailer in TITAN factory

2. Gooseneck of low bed trailer

TITAN low bed trailer main beam gooseneck lower has a reinforcement, gooseneck double plat. The trailer in the heavy load when the deformation range is very small, better to use.

3. Ramp of low bed truck

The ramp of low bed truck is welded with H60 steel of high strength steel plate, which has strong bearing capacity and effectively ensures that the weight of excavator or other heavy equipment can pass through the spring ramp without deformation or damage.

The low bed truck trailer ramp adopts four-in-one high-strength board, which has high strength, durability and no deformation. Using high elastic double spring climbing ramp, ordinary people can easily lift with one hand, which is more convenient to operate.

The service can up to more than 5 years, other factories use channel steel welding, it is easy to deformation collapse.

After the lowbed trailer is produced, all of TITAN low bed truck trailers are tested to ensure that our low bed trucks are free of problems. All low bed truck for sale is tested for carrying capacity after production is finished.TITAN has dedicated technical staff to guide the operation.

When transporting lowbed truck trailer, many customers choose bulk carriers or ro-ro ships, which has low transportation costs and short transportation time. When the lowbed truck trailer size is small, some customers choose to use container transportation.

TITAN low bed truck have professional staff to make a package, all of them were trained constantly. Please notice that to prevent the low bed trailer truck paint from being corroded by seawater to we spray a layer of wax on the surface of the low bed semi trailer before shipping. And covering poncho to prevent the damp condition.

Package of TITAN 4 axle lowbed trailer for sale

The lowbed trailer is a kind of machinery transport use trailer with a much lower working platform, with a high range of 400mm to 1200 mm. The high of the working platform for low bed trailer usually depends on the loading capacity and the equipment that will be transported.

Lowbed trailer has several types including normal type lowbed trailer, heavy-duty lowbed trailer, dual lane axle low bed trailer, detachable low bed trailer, extendable type low bed trailer, modular type low bed trailer, etc. Here below, let check on these types of low loader trailers one by one.

1. Normal type lowbed trailer:

This normal-type lowbed trailer is the most popular type lowbed trailer with a loading capacity from 20 - 80 tons, the lowbed trailer equipped with 2-4 axles, model for 13-20 ton axles. Usually equipped with the spring ladders for the machines such as the wheel loaders, excavators, or some different types of wheeled machines transportation. The high of the working platform is various from 1000mm to 1200mm.

2. Heavy duty type lowbed trailer:

Heavy duty lowbed trailer is almost the same as the normal type lowbed trailers, only comes with a higher loading capacity normally from 80 tons to 140 tons. This type of lowbed trailer is a cost-effective type, usually used for those countries which don't have the special requirements on the axles load and the off-road working environment.

4 axle lowbed trailer VS 4 line 8 axle lowbed trailer

4 axle lowbed trailer VS 4 line 8 axle lowbed trailer

3. Dual lane axles low bed trailers:

The main specification for the dual-lane low bed trailer is its axles. The dual-lane axle low bed trailer equipped with the short axles, each line has two short axles with 8 sets of tires and rims. This type of low bed trailer is usually used for super heavy equipment transportation. The working platform length will be designed according to the machines that will be transported, tire covered, or exposed types.

4. Detachable low bed trailer:

Detachable low bed is a specially designed type of low bed trailer without ladders on the rear, it's a front-loading type low bed trailer. This type of low bed trailer has a super low working platform, normally on 400mm. This design is used for super heavy equipment transportation. Normally over 100 tons. It's an oversized transportation low bed trailer with a width of 3000mm to 4000mm, the length is normally 16000-17000mm. The detachable low bed trailer can be designed according to the customers' special requirement.

5. Extendable low bed trailer:

The extendable low bed trailer is a kind of special low bed trailer which is designed for the oversized cargo delivery. This type of lowbed trailer usually doesn't have the ladder, because it's special used for the heavy equipment transportation such as the wind tower transport. Extending low bed trailer usually has two types, it's width-extendable and length-extendable, two types. The side extending type low bed trailer is usually used for the width oversized cargo delivery, the width of the extending low bed trailer is different from 3000mm to 5000mm. Length extending type low bed trailer is used for the length of oversized cargo delivery. The length after extended can be up to 25000mm. The special type is the width and length both extendable low bed trailers, usually used for wind tower transportation.

4 axle extendable low bed trailer

Lowbed trailers are widely used in different fields due to their advantages over a flat bed. The main advantages are summarized below.

Versatility

One of the reasons why many companies buy lowbed trailers is that they are so versatile. The structure of the lowbed trailer allows the company to easily transport such a wide cargo. Keep in mind that trailers can also handle ultra-high cargo.

In most cases, heavy machinery and equipment are very wide. A company that handles different types of goods does not need to buy different trailers for each category. As long as the goods are packaged correctly, the lowbed truck trailer can transport any type of goods.

3 Axle 100 Ton Lowbed Trailer with Folding Ramp

Meet height restrictions

Some countries have laws restricting the height of goods that can be transported on the road. Loading tall equipment on trailers is often a huge challenge for transportation companies.

Low bed trailer for sale provide companies with a solution to safely transport ultra-high equipment without breaking the law.

Stability

Compared with flat bed trailer, lowbed trailer for sale deck is excellent. A lower deck means a lower center of gravity. Therefore, low bed truck trailer is more stable than trailers when transporting heavy goods.

One way to increase stability is to expand the support base. For lowbed trailer for sale, this is possible because the width of the cargo plane can be widened. Regardless of the height and weight of the cargo, the trailer can remain stable on the road.

4 Axle Lowbed Trailer Truck

TITAN lowbed trailer for sale loading ramps are made by high strength steel, with high loading capacity, which will not happen to the deformation when carrying heavy equipment. There are several different types of ramps that can be used with a lowbed trailer, depending on the specific needs of the user. Here are some common types of ramps:

1. Mechanical Spring Ramps

These are permanently attached to the lowbed trailer and cannot be removed. They are usually made of steel and are ideal for transporting heavy equipment. This type of ramp is designed with a hinge mechanism that allows the ramp to be easily raised and lowered.

2. Hydraulic Ramps

These ramps are operated by a hydraulic system, which makes them easy to raise and lower. This makes it much easier to load and unload heavy equipment or vehicles, as the ramp can be adjusted to the appropriate height with just the push of a button or lever. They are ideal for loading and unloading heavy equipment quickly and efficiently.

3. Folding Ramps

The folding ramp is designed to fold and store neatly when not in use, which makes it easier to transport the lowbed trailer without taking up too much space. It is attached to the back of the trailer and can be unfolded for loading and unloading. Using a longer ramp reduces the slope, which makes it easier to move heavy cargo.

4. Detachable Ramps

These ramps can be detached from the lowbed trailer and stored separately when not in use. This can be helpful if you need to transport different types of cargo that require different ramp configurations.

Landing gear lifting system: In order to make the lowbed trailer for sale reliably parked after being separated from the truck, the front end of the frame is provided with two linkage or single action landing gear. It consists of a screw drive mechanism, a bevel gear drive mechanism, a two-speed reduction gearbox, a transmission rod, an operating handle, and so on.

Traction pin: There is a traction pin connection plate connected to the tractor saddle at the lower part of the front end of the frame. The traction pin is mainly used to transmit the traction of the tractor and the braking force during braking.

Ramp: There are three styles of lowbed trailer ramps, the most common is spring ladders. There are also ordinary hydraulic ramps and folding hydraulic ladders.

Suspension system: transfer load and absorb vibration.

Axle and hub system: A single, two and three axle assemblies of the same structure are installed under the suspension system.

Semi trailer braking system: It is composed of the trachea connector, inflation pipe, operating channel, gas reservoir, brake air chamber, relay valve, ABS valve, ABS sensor and wheel brake of the tractor.

The inflatable tube is connected to the tractor gas tank through a quick pipe joint; it is connected to the tractor brake valve through a quick joint. When the lowbed trailer brakes, each brake air chamber functions simultaneously.

Semi trailer airway: Three major parts: emergency relay valve, ABS valve, brake air chamber, most of the faults come from these three pieces.

Semi trailer circuit: The lowbed truck transmits the light signal of the main vehicle to the trailer by connecting the spiral cable plug of the truck to the circuit socket at the front of the trailer. Thus, the vehicle equip with an international general electrical system that matches the truck. The electrical system generally consists of seven core sockets, multi core cables, junction boxes, waterproof connectors, and various types of lamps and other components.

The cost of a low bed trailer can vary significantly based on factors such as brand, size, capacity, and features. On average, a new low bed trailer could range anywhere from $13,000 to $30,000 or more, depending on the specifications.

For the most current and accurate pricing, welcome contact us to get the latest prices.

Several factors can influence the price of a low bed trailer:

1. Size and Capacity: The dimensions and load capacity of the low bed truck trailer can significantly impact the price. Larger trailers with higher weight capacities tend to be more expensive.

2. Materials and Construction: The quality of materials used in the low bed truck trailer's construction, such as steel or aluminum, can affect the price. Trailers built with high-grade materials may cost more.

3. Features and Customizations: Additional features such as ramps, hydraulic systems, adjustable axles, and other customizations can increase the cost of the low bed trailer.

4. Brand and Reputation: Well-known brands or manufacturers may command higher prices due to their reputation for quality and reliability.

5. Market Demand: Supply and demand dynamics in the low bed truck trailer market can also impact pricing.

6. Additional Costs: Consider additional costs like delivery fees, taxes, registration, and any optional accessories.

To get an accurate price for a specific low bed trailer, it's best to contact dealerships, manufacturers, or suppliers for detailed quotes based on your requirements.

The terms "lowboy" and "lowbed" both refer to types of trailers designed to transport heavy equipment, but there are some key differences between them. Lowboy trailer commonly used in construction, heavy machinery, and oversized loads. Lowbed trailer for sale used for transporting heavy machinery, but not as versatile for oversized loads compared to lowboy trailer.

Lowboy trailer features a detachable neck that can be lowered to the ground, allows for direct loading of heavy equipment. But lowbed trailer has a fixed low deck height with multiple axles for weight distribution, the neck is not detachable. Lowboy trailer easy ground-level loading without ramps, it ideal for very heavy or oversized items. Lowbed trailer for sale loads are typically driven onto the trailer using ramps, may not accommodate direct loading for very tall items as easily.

Lowboy trailer generally heavier and more expensive due to added features and stability requirements. Lowbed trailer price lighter and more economical due to simpler construction.

Lowbed Trailer

A lowbed trailer is a type of trailer designed for transporting heavy and oversized cargo, featuring a low-profile deck that enhances stability and accessibility. Here’s a detailed description:

Features of a lowbed trailer:

1. Heavy Duty Gooseneck: Lowbed trailer constructed from high-strength steel, ensuring durability and resistance to deformation under heavy loads.

2. Loading Ramps: Lowbed trailer equipped with spring or hydraulic ramps that facilitate smoother loading and unloading processes for heavy machinery.

3. Multiple Axles: Lowbed trailer equipped with multiple axles (typically ranging from two to five or more) to distribute weight evenly and improve stability when transporting heavy loads.

4. Versatile Configuration: Lowbed trailer can come in various configurations, including fixed and expandable decks, providing options for different transport needs.

5. Safety Features: Lowbed trailer designed with safety in mind, including tie-down points for securing loads, reflective materials for visibility, and braking systems tailored for heavy loads.

Advantages of lowbed trailer:

1. Lower Loading Height: The low deck of lowbed trailer for sale allows for easier loading and unloading of tall equipment, reducing the risk of damage during transport.

2. Increased Stability: The low center of gravity helps improve overall stability while transporting heavy loads, reducing the likelihood of tipping.

3. Enhanced Weight Distribution: Multi-axle configurations distribute weight more evenly across the axles, allowing for compliance with road regulations and reducing wear on road surfaces.

4. Safety Features: Lowbed trailer for sale equipped with tie-down points, reflective markers, and sometimes hydraulic braking systems, these trailers enhance safety during transport.

5. Flexibility in Transport: Lowbed trailer for sale suitable for a variety of industries, including construction, agriculture, and mining, lowbed trailers can adapt to many types of heavy equipment.

Lowboy Trailer

A lowboy trailer, often referred to as a "detachable gooseneck trailer" or "removable gooseneck trailer" is designed specifically for transporting heavy equipment and loads. Here’s a detailed description:

Features of a lowboy trailer:

1. Detachable Gooseneck: The gooseneck, which is the front part of the trailer that connects to the towing vehicle, can be detached. This allows for easy loading and unloading of larger machinery since the lowboy trailer can be lowered to the ground.

2. Low Deck Height: The design of lowboy trailer includes a low deck height that minimizes the overall height of the load, making it suitable for transporting taller equipment without exceeding height restrictions.

3. Versatile Loading Options: The ability to detach the gooseneck allows for a more flat and accessible loading area. Lowboy trailer equipment can be driven on at a low angle, making it easier and safer to load heavy machinery.

4. Heavy-Duty Construction: Lowboy trailers are built to withstand significant weight and are often constructed from robust materials to handle tough hauling conditions.

Advantages of lowboy trailer:

1. Easy Loading and Unloading: The detachable gooseneck design allows for a low deck height, making it easier to drive heavy machinery on and off the lowboy trailer. This can significantly reduce the time and effort required for loading and unloading.

2. Detachable Gooseneck: Lowboy trailer feature a detachable neck, making it easier to load heavy equipment directly onto the trailer without ramps.

3. Legal Load Capacities: Lowboy trailers are designed to carry heavy and oversized loads while complying with legal weight and height limits, making them suitable for a variety of heavy transport needs.

4. Improved Maneuverability: The gooseneck design allows for better maneuverability compared to traditional trailers. This can be especially beneficial in tight spaces or during difficult loading operations.

5. Customization Options: Lowboy trailer can often be customized to fit specific transportation needs, including different lengths, axle configurations, and additional features.

lowbed trailer , lowbed for sale , 100t lowbed for sale , lowbed trailer for sale , lowbed trailer truck , 4 axle lowbed trailer

3 axle Low bed trailer for sale

lowbed trailer for sale

100t lowbed trailer for sale

4 line 8 axle 150 ton lowbed trailer