Chapter 1: What is a removable gooseneck trailer?

Chapter 2: What types of detachable gooseneck trailer?

2.1 Common structure of detachable gooseneck trailer

2.2 The first type of the detachable gooseneck trailer

2.3 The second type of the removable gooseneck trailer

2.4 Operation and characteristics of hydraulic lowboy trailer

Chapter3: Points to consider when purchasing a detachable trailer.

3.1 Frame of gooseneck hydraulic low bed trailer

3.2 What is the difference between the steel used for the detachable trailer?

3.3 What is the load of the detachable trailer for sale.

3.4 How high off the ground is a detachable trailer?

Chapter 4: Detachable gooseneck trailers carrying experiment and marine transportation.

Chapter 5: Characteristics of the lowboy gooseneck trailer.

6.1 Mechanical detachable gooseneck structure principle

6.2 Air removable gooseneck structure principle of the removable gooseneck trailer

removable gooseneck trailer for sale has many different names in different countries around the world, such as RGN trailer, detachable gooseneck trailer, folding gooseneck lowboy trailers, hydraulic low bed trailer, removable gooseneck trailer, front loading rgn lowboy trailer, and military lowboy trailer for sale.

Loading method for removable gooseneck trailer: cargo is loaded from the front. Detachable gooseneck cargo table is only 85 cm, the center of gravity is very low, so the stability and security are very good. As you can see, the removable gooseneck trailer can transport ultra-high and medium sized equipment and machine.

3 Axle 60/80 Ton Removable Gooseneck Trailer

4 Axle Removable Gooseneck Trailer with 2 Axle Dolly

The hydraulic detachable gooseneck trailer uses a concave beam type. Detachable gooseneck trailer can separate the gooseneck from the trailer, and achieve contact between the front end of the vehicle and the ground. After the cargo or equipment is loaded, the RGN trailer is restored to the original transportation state in time for transportation.

Common detachable gooseneck trailer, should use the ramp behind the used lowboy trailer for cargo loading. Yet, some large machinery and equipment, such as pile drivers, large rotary drills, large excavators, and large bulldozers, have very high centers of gravity due to their very high height. There is a great risk of later loading.

The stretch detachable gooseneck trailer has many different structures. There are two structural styles. Then we use pictures and text to explain it. TITAN removable gooseneck trailer dimensions can be customized according to your requirements.

It is mainly designed to transport 30 tons, 60 tons, 80 tons, 100 tons, 120 tons of heavy equipment or machinery.

The main styles are 2 axles, 3 axles, and 4 axles.

It is mainly designed to transport 100 tons, 120 tons, 150 tons of heavy equipment or machinery.

The main use is the line axle structure. 2 lines 4 axles, 3 lines 6 axles, and 4 lines 8 axles.

Detachable gooseneck trailer for pickups truck

Mechanically detachable gooseneck operation: In the process of removing the gooseneck, the front gooseneck of the trailer must be separated from the saddle of the truck. After the disassembly is completed, the equipment can be loaded.

Detachable gooseneck trailer features: Because this trailer has a low center of gravity and a long cargo table, it can transport a lot of goods. The maintenance cost is also very low, the structure is easy to assemble, and the weight is light. Thus, the rgn trailer for sale near me is the preferred type that many transportation companies sell.

There are a variety of different transport semi trailers in the Chinese transport market, as many of them are locally transported and so common low bed trailers are more. Every city in China is under construction and is basically equipped with construction machinery and equipment, so long-distance transportation of large machines such as heavy excavators is not required.

But, the hydraulic removable gooseneck trailers produced by TITAN detachable trailer manufacturers are mainly exported to Central and West African countries such as Nigeria and Tanzania, and more than 200 units have been produced. Technology is mature.

The effective load surface length of the frame is generally 5500mm to 9000mm, the width is 3000mm to 36000mm, and the widest can be 4 meters wide.

Currently, the main steel type used for gooseneck lowboy trailers is HG60. HG60 is high-strength structural steel with high toughness, good fatigue resistance, welding performance and corrosion resistance.

HG60 high strength steel: C≤0.18 Si0.15 ~ 0.40 Mn1.00 ~ 1.70 P≤0.030 S≤0.025 Mo-Cr-Nb0.02 ~ 0.06 V0.03 ~ 0.08 Ni- HG60

Tensile test: Ret≥450MPa Rm570 ~ 720MPa A50≥19

Common lowbed trailers use Q345 manganese steel. Q345 steel cannot be used to transport heavy equipment.

TITAN can be customized heavy duty detachable trailer according to actual load requirements. Common design load tonnages are 60 tons, 80 tons, 100 tons, 120 tons, 150 tons, fixed rgn equipment trailer max weight reaches 200 tons.

The height of the TITAN military pj detacahble gooseneck trailer plate can be customized. The common design of the height of the working surface is 850mm, and 800mm and 900mm. The height of the working surface can be controlled by the hydraulic system during actual transportation.

After the production of all hydraulic detachable goosenecks, pressure tests will be performed.

To prevent the 53 foot tilt deck extendable gooseneck trailer paint from being corroded by seawater, we spray a layer of wax on the surface of the lowboy trailer before shipping, and then seal it with a waterproof rain cloth.

35 ton fixed neck paver double drop detachable gooseneck trailer for sale

1. Strong carrying capacity

Most of this type of Lowboy Gooseneck Trailer has large tonnage, so the body is mostly designed with an arched cargo bed, and the longitudinal beams are mostly multi-longitudinal high-strength steel structures, which reduces the weight and improves the carrying capacity.

Lowboy trailer's main beam of TITAN is made of HG60 high-strength structural steel. The yield strength of HG60 steel is ≥ 620MPa, which is more durable and stronger than ordinary steel. Its bearing capacity is 5 times of that of Q345 steel trailer. TITAN lowboy trailer adopts reinforced the gooseneck and upper and lower plate by double layer.

2. Low center of gravity and good stability.

Due to the low ground clearance and low longitudinal beam height of this kind of Lowboy Gooseneck Trailer, the load-bearing surface is 300-400mm lower than that of the normal concave-center removable lowboy semi-trailer, thereby effectively reducing the height of the center of gravity of the loaded goods and improving the stability during transportation.

Oilfield trailers bottom plate, Other suppliers usually use 3 or 4 mm bottom plate, But TITAN adopt 5 mm thick bottom plate, It’s more durable and won’t be deformed.

3. Good performance

The cargo bed load-bearing surface of the lowboy trailer can be adjusted to the ground height by a hydraulic device as needed, and when it passes through culverts or bumpy roads, the cargo bed load-bearing surface can be lowered or raised to improve its passing performance.

4. The effective length of the cargo bed is long

Because this type of model eliminates the rear ladder, the bearing surface can be lengthened, and because the construction machinery does not go from the rear, the slope angle in front of the bridge can be appropriately increased, so that the bearing surface can be lengthened. The length of the low flat cargo table with a ladder at the end is longer, which can effectively load more loads, indirectly improve the loading efficiency, and create greater benefits for users.

5. Easy maintenance of the Lowboy Gooseneck Trailer

Because the bearing surface can be raised and lowered, the tires on a bridge can be grounded, and other tires can be safely and conveniently replaced or other maintenance work without detaching.

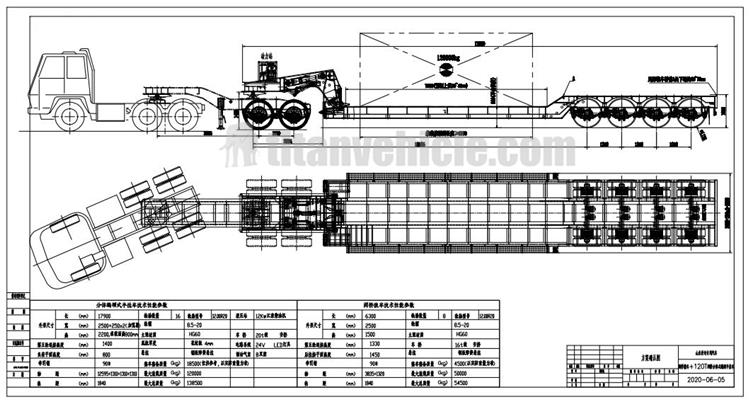

4 Axle Lowboy Gooseneck Trailer with Dolly Drawing

4 Axle Lowboy Gooseneck Trailer with 2 Axle Dolly Drawing

4 Axle Lowboy Gooseneck Trailer with 2 Axle Dolly Drawing

6.1 Mechanical detachable gooseneck structure principle of the detachable trailer

The mechanically detachable gooseneck frame of the removable gooseneck trailer is similar to the lowboy gooseneck trailer body frame, and both are symmetrical with respect to the longitudinal vertical center plane. And indirectly contact with the ground (supported by the ground). The front end of the gooseneck is connected with the traction saddle of the tractor through a traction pin. The relationship between the tractor and the gooseneck is that the tractor can rotate around the blood axis relative to the gooseneck. After being separated from the towing saddle, the tractor can be driven away from the semi-trailer. The part of the tractor and the traction saddle (or becomes part of the traction saddle) is often made into inclined planes 1 and 2 with different inclination angles that tilt backward and downward with respect to the ground. The front end of the gooseneck lowboy trailer body Tilt the plane forward and downward to align with the upward tilting plane at the lower end of the gooseneck. This structure is arranged after the gooseneck is in direct contact with the gooseneck lowboy trailer. A continuous contact plane can be provided between the two. In order to further cooperate and connect the two.

The front end of the detachable gooseneck trailer body is adjacent to the rear end of the dumping plane with a slot, the size of which is just enough to allow the protruding rod at the rear end of the gooseneck to be inserted. The convex rod not only includes a supporting neck. It also includes a freely extending raised portion. Its shape is L shape. The protruding rod can be in adjacent contact with the limit stop block which is stolen orthogonally on the semi-trailer body. The position of the protrusion can be defined by an orthogonal pin at the front end of the material surface. The function of the compression spring between the pin head and the fixed connecting plate is to restrict the protrusion from moving longitudinally along the gooseneck lowboy trailer. Prevent the gooseneck from detaching from the gooseneck lowboy trailer. The tail of the bolt is hinged to the connecting rod and then to the horizontal rocker through the connecting rod.

The horizontal rocker is then hinged with the vertical rocker. Therefore, the latch can be retracted by pulling the handle at right angles to the vertical rocker manually (through the circular notch on the side of the car body). In order to remove the obstacles to the longitudinal and longitudinal movement of the protrusion, when the handle is rotated counterclockwise, the latch is released under the pull of the horizontal rocker and moves away from the center. The protrusion at the end of the protruding rod moves backward toward the limit stop, and is retracted by pressing the inclined surface of the latch, and finally contacts and presses the limit stop. After that, the bolt springs back under the action of the compression spring and prevents the protrusion from moving out: in this way, the gooseneck and the semi-trailer are bolted together and become a whole, which can move back and forth and laterally.

The gooseneck and detachable trailer usually need to rotate around an orthogonal horizontal axis in the area of the sowing position. For this reason, the dumping plane is combined with the relatively flat part of the removable gooseneck trailer where the plane is close to the position of the latch mechanism, and the gooseneck is designed with a round end so that the gooseneck can swing on the flat surface of the gooseneck lowboy trailer. The size of the bolt and the slot hole meets that the sowing tip can rotate freely in the slot hole. When the gooseneck and the semi-trailer are connected by an inclined plane and another inclined plane, the weight of the removable gooseneck trailer will be transmitted, and the gooseneck will be borne by a special connecting mechanism. Each side of the bifurcated gooseneck is fixed with a stationary pin, and its rear end is tapered and fixed to the gooseneck; its front end extends horizontally in the forward direction and is connected to the goose by welding by a steel belt below the neck arch structure.

Feedback of the removable gooseneck trailer from customer

Detachable gooseneck trailer with dolly ready for shipment

6.2 Air removable gooseneck of the removable gooseneck trailer

The disassembly of the air detachable gooseneck trailer gooseneck completely relies on compressed air from the air brake system of the tractor. No additional equipment is needed, so the weight is lighter. There is no need for expensive maintenance costs.

Air detachable gooseneck structure principle of the detachable gooseneck trailer

The air detachable gooseneck includes a horizontal longitudinal beam that can be connected to the tractor saddle and a vertical part whose upper end projects horizontally forward. The vertical part and the horizontal longitudinal beam are connected together at the forward projecting part. And can rotate around the axis orthogonal to the longitudinal beam. The rear end of the horizontal longitudinal beam is offset from the hinge axis by a certain distance and is flush with the rear end of the main vertical part. There is a fixed platform on the main vertical part, on which two airbags communicating with the braking system of the tractor are fixed.

The upper end of the airbag is against the lower plane of the rear end of the horizontal longitudinal beam. The lower end of the main vertical part is connected to the front end of the removable gooseneck trailer, and its fixation is achieved by a telescopic pin installed at the rear end of the main vertical part and inclined downward (the telescopic pin can extend into the corresponding tilt pin on the front end of the removable gooseneck trailer hole). The main vertical part also includes two downwardly extending orifice plates. Used to receive the horizontal telescopic pin of the removable gooseneck trailer. A series of pin holes are opened at the upper part of the rear end of the main vertical part.

Two cooperating telescopic pins are installed near the rear end of the horizontal longitudinal beam. These pin holes can provide the desired locking position during the driving of the removable gooseneck trailer. When adjusting the height of the gooseneck lowboy trailer, the airbag is inflated to lift the rear end of the horizontal longitudinal beam, and then the semi-trailer is lifted to the desired level and then the pin is locked in the appropriate hole position.The two horizontal longitudinal beams are contained in two basically similar side structures including vertical parts, and provide space for other components. The horizontal longitudinal beam is hinged to the forward protruding part of the upper end of the vertical part through a pin shaft, and the hinge shaft passes through the pin hole on the forward protruding part and the pin hole on the side of the horizontal longitudinal beam.

The telescopic pin on the rear end of the horizontal longitudinal beam can be inserted into any pin hole on the vertical grid. Two orifice plates extend downward on both sides of the front of the vertical part, each orifice plate can receive the horizontal telescopic pin at the front end of the lowboy gooseneck trailer when the lowboy gooseneck trailer is assembled, and the vertical part also includes a side vertical plate. The side vertical plate is integrated with the vertical part, and there are three rows of bolt holes. Between the two vertical boards is a platform. There are two rows of bolt holes on both sides of the platform, so by selecting the appropriate bolt holes, it can be fixed to the selected horizontal position. A series of circular structures are arranged on the upper surface of the platform, whose function is to provide bolt holes for receiving and fixing the airbag. The airbag has a telescopic nature, and can expand or contract along its length as the air pressure acting on it changes.

Up to 5 airbags can be installed on the upper surface of the platform. The horizontal longitudinal beam is located in the structure on both sides of the vertical part. The bottom surface of the rear end is equipped with an upper top plate of the airbag. The plate faces the upper plane of the platform downward, and the lower surface is a plane. And has a structure to fix the upper end of the airbag. The upper top plate side of the airbag is regarded as an upright triangle shape, the most distant end of which faces upward, and a circular groove is opened for installing the receiving sleeve. The upper top plate of the airbag is hinged to the fixed support on the lower surface of the horizontal longitudinal beam through a pin shaft, so that it can make a limited swing around the pin shaft. In addition to the airbag, two cylinders are installed vertically between the platform and the upper roof of the airbag.

The corresponding live rods are piston rod a and piston rod b. The cylinder a and the cylinder b are forked at the bottom so as to be hingedly mounted on the lower ear-shaped support protruding upward from the platform. The top of the piston rod is hingedly mounted on the upper ear-shaped support protruding downward from the upper top plate of the airbag. The cylinder is connected with the air brake system of the tractor to raise or lower the vertical part and connect the gooseneck to the half. The airbag is compressed at the front end of the trailer in order to precisely adjust the height of the goose of the gooseneck lowboy trailer. The two basic horizontal longitudinal beams may be equipped with air reservoirs, one end of which is connected with the air brake system of the tractor, and the other end is connected with the airbag. The cylinder adjusts the height of the gooseneck, horizontal rail and gooseneck lowboy trailer through suitable connection methods, such as valves and controllers. The structure and principle of the ejection and shrinkage locking pin mechanism are described below.

A cylinder connected with an air source is installed on the beam at the rearmost end of the horizontal longitudinal beam. The piston rod moves forward and backward as the air pressure changes. The rear end of the movable rod is bifurcated and hinged with the connecting rod. The connecting rod is hinged with the horizontally arranged upper plate near its midpoint (the midpoint of the plate). One end of the upper plate is connected to the cross beam between the horizontal longitudinal beams through a spring, and the other end is installed on the upper end of the vertical pin shaft, which is hinged on the orthogonal cross beam rod between the horizontal beams.

Welcome to leave your inquiry!

We will meet the acme of perfection to serve and provide more details, price, catalog, drawing, videos for you!